Fiber Optic Sensors Laboratory

Fiber Optic Sensors Laboratory

| Head of the laboratory: | prof. dr hab. Ryszard Buczyński |

| Localisation: | ul. Pasteura 5, B4.32 |

| Institute: | IG |

| Department: | PD |

The Fiber Optic Sensors Laboratory focus is the application of various types of optical fibers and their optimization in terms of sensor construction. The research covers both simulation and design works, as well as the fabrication of optical fibers and their use in sensors. The laboratory carried out, among others, sensors for measuring ethanol concentration, for label-free detection of biomarker concentration, for measuring gas concentration, and for measuring the refractive index of liquids. Birefringent optical fibers and fibers with recorded Bragg grating are also being developed, which can be used in various types of optical sensors.

Research area

Various types of optical fibers that we design and manufacture is the starting point of the construction of sensors.

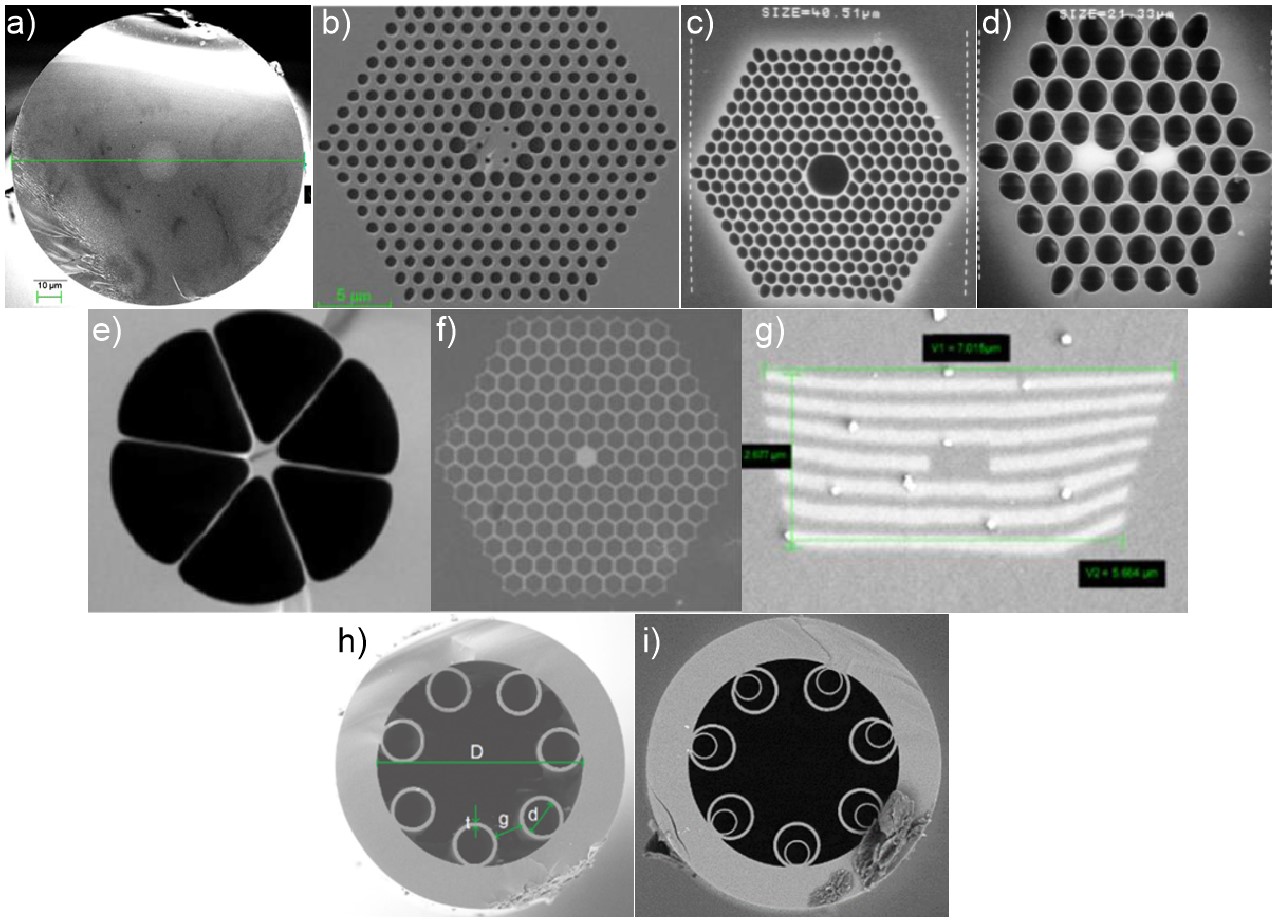

Fig. 1 An example of optical fibers developed by the research group: a) optical fiber with a microstructural core, b) photonic optical fiber with a glass core, c) hollow-core photonic optical fiber, d) optical fiber with two cores, e) optical fiber with a suspended core, f) all-glass photonic optical fiber, g) birefringent optical fiber, h) anti-resonant optical fiber, i) nested-capillary anti-resonant optical fiber.

Each of the optical fibers can potentially be a component of the sensor. The optical fiber can be used both as an element whose task is only to bring and receive light to and from the appropriate sensor and as the actual measuring element. In the latter case, the measured quantity should be related to some property of the electromagnetic wave which changes, e.g. intensity, phase, polarization or wavelength, or with the change of the light propagation conditions in the optical fiber.

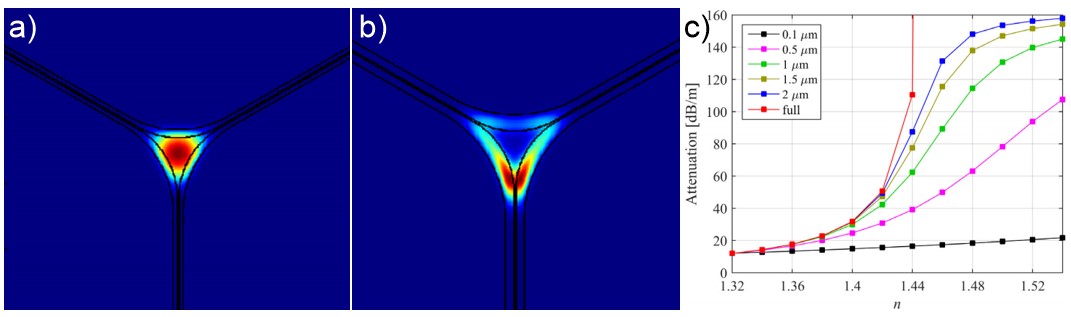

Intensity sensor

An example of a sensor that uses a change in light intensity is e.g. a sensor for label-free biological measurements. In this case, a fiber with a suspended core is used. The growth of the biological layer on the fiber core causes a change in the refractive index around the fiber core. This way the propagation conditions change and, as a result, some light escapes from the core. The decrease in intensity observed at the exit of the optical fiber is proportional to the thickness of the biological layer deposited on the core. A similar principle can be used to build a sensor to determine the concentration of a specific biological substance, e.g. protein. If you want to find out whether a given solution contains, for example, a given protein, you must somehow sensitize the optical fiber to this specific substance. A functionalization technique is used for this purpose. It consists of covering a part of the core with a substance that will selectively bind only to a given protein. The change in intensity observed at the output of the optical fiber proves not only that a given protein is present in the tested solution, but also allows to determine the concentration of a given protein.

Fig. 2 Intensity sensor for label-free biological measurements based on a suspended core fiber: a) light guidance in the fiber core, b) light escape to the biological layer, c) dependence of the beam weakening on the thickness of the deposited layer.

Phase sensor

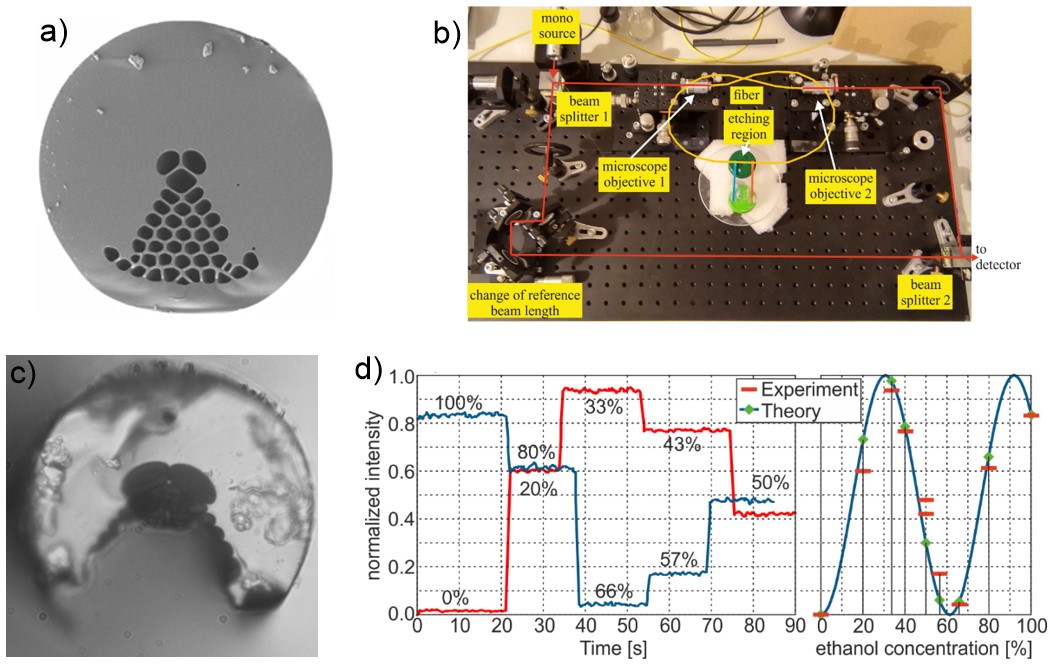

An example of a fiber optic sensor that uses the phase change of light is e.g. a sensor for measuring the concentration of ethanol in water. The sensor is built on a suspended core fiber. In order to allow free access of the test liquid to the core, part of the fiber was etched. Changing the concentration of ethanol in the water changes the refractive index of the liquid. However, this change is so too small that the direct measurement is insufficient. Therefore, the measurement is made in an interferometric system. In one arm of the interferometer, there is an optical fiber with an exposed core. The change in concentration causes a change in the refractive index which results in a change in propagation conditions and, as a result, in a change in the optical path. The second arm, the reference arm, has a fixed length. The result of the interference of both signals at the sensor output makes it possible to determine the concentration of ethanol in the water.

Fig. 3 The interferential sensor of ethanol concentration in water: a) suspended core fiber before etching, b) etched optical fiber, c) interferometric system, d) concentration measurement result.

Publications

T. Osuch, A. Anuszkiewicz, D. Zakrzewski, A. Filipkowski, J. Olszewski, P. Mergo, D. Pysz, R. Kasztelanic, R. Buczynski, Enhancement of spectral response of Bragg gratings written in nanostructured and multi-stepped optical fibers with radially shaped GeO2 concentration, Opt. Express, 28(10), 14774-14787 (2020).

D. Michalik, T. Stefaniuk, R. Kasztelanic, R. Buczynski, Polarization maintaining optical fiber with anisotropic core compatible with SMF-28 standard, JOSA B, 37(5), 1502-1509 (2020).

J. Hu, G. Gu, Y. Liu, X. Song, Z. Song, X. Yang, D. Xiao, S. Yang, J. Feng, R. Buczyński, M. Śmietana, T. Lang, L. Shao, Dual Mach-Zehnder interferometer based on side-hole fiber for high-sensitivity refractive index sensing, IEEE Phot. Jour., 11(6), 7105513 (2019).

M. Nikodem, G. Gomolka, M. Klimczak, D. Pysz, R. Buczynski, Demonstration of mid-infrared gas sensing using anti-resonant hollow-core fiber and quantum cascade laser, Opt. Express, 27(25), 36350-36357 (2019).

D. Dobrakowski, G. Stepniewski, R. Kasztelanic, R. Buczynski, M. Klimczak, Birefringence of nonlinearity in all-normal dispersion photonic crystal fibers, J. Opt., 21 125502 (2019).

T. Osuch, A. Anuszkiewicz, K. Markowski, A. Filipkowski, D. Pysz, R. Kasztelanic, R. Stepien, M. Klimczak, R. Buczynski, Inscription of Bragg gratings in nanostructured graded index single-mode fibers, Opt. Express 27(10), 13721-13733 (2019).

R. Kasztelanic, A. Filipkowski, D. Pysz, R. Buczynski, Optical fibers with an open side channel by wet etching, Opt. Express, Opt. Express 26(25), 32374-32387 (2018).

H.V. Le, V.C. Long, H.T. Nguyen, A.M. Nguyen, R. Buczyński, R. Kasztelanic, Application of ethanol infiltration for ultra flattened normal dispersion in fused silica photonic crystal fibers, Laser Phys. 28 115106 (2018).

A. Anuszkiewicz, R. Kasztelanic, A. Filipkowski, G. Stepniewski, T. Stefaniuk, B. Siwicki, D. Pysz, M. Klimczak, R. Buczynski, Fused silica optical fibers with graded index nanostructured core, Sci. Rep 8, 12329 (2018).

H.L. Van, R. Buczynski, V.C. Long, M. Trippenbach, K. Borzycki, A. N. Manh, R. Kasztelanic, Measurement of temperature and concentration influence on the dispersion of fused silica glass photonic crystal fiber infiltrated with the water-ethanol mixture, Opt. Comm. 407, 417-422 (2018).

L.C. Van, A. Anuszkiewicz, A. Ramaniuk, R. Kasztelanic, K.D. Xuan, V.C. Long, M. Trippenbach, R. Buczyński, Supercontinuum generation in photonic crystal fibres with core filled with toluene, J. Opt. 19, 125604 (2017).

J. Pniewski, A. Ramaniuk, R. Kasztelanic, M. Śmietana, M. Trippenbach, R. Buczyński, Applicability of suspended-core fibers for attenuation-based label-free biosensing, Opt. Comm. 402, 290-295 (2017).

J. Pniewski, T. Stefaniuk, H. Le Van, V. Cao Long, L. Chu Van, R. Kasztelanic, G. Stepniewski, A. Ramaniuk, M. Trippenbach, R. Buczynski, Dispersion engineering in nonlinear soft glass photonic crystal fibers infiltrated with liquids, Appl. Opt. 55(19), 5033-5040 (2016).

G. Stępniewski, I. Kujawa, M. Klimczak, T. Martynkien, R. Kasztelanic, K. Borzycki, D. Pysz, A. Waddie, B. Salski, R. Stępień, M.R. Taghizadeh, R. Buczyński, Artificially anisotropic core fiber with ultra-flat high birefringence profile, Opt. Mat. Express, 6(5), 1464-1479 (2016).

R. Buczyński, M. Klimczak, T. Stefaniuk, R. Kasztelanic, B. Siwicki, G. Stępniewski, J. Cimek, D. Pysz, R. Stępien, Optical fibers with gradient index nanostructured core, Opt. Express, 23(20), 25588-25596 (2015).

Realted documents:

- 1. Przepisy BHP

| Femtosecond laser 1560 and 780 nmlaser |

| BlueCut femtosecond laserlaser |

| Chromatic dispersion measurement system for optical fibresoptical system |

| Dispersion of glasses and liquids measurement systemoptical system |

| X-Frogoptical system |

| Z-scanoptical system |